The Ocotillo Services receiving warehouse serving Indio understands the significance of optimizing warehouse efficiency. Interior designers play a crucial role in creating a space that maximizes productivity while reducing costs. With the evolving demands of modern commerce, businesses are constantly seeking innovative ways to improve warehouse operations. Together, let’s explore practical ideas and strategies to enhance the efficiency and productivity of the Ocotillo Services receiving warehouse servicing Indio.

1. Implement Lean Principles

Embrace lean principles to streamline warehouse operations and eliminate waste:

- Just-in-Time Inventory: Adopt a just-in-time inventory approach to minimize excess inventory, reduce storage costs, and catch vendor errors immediately.

- Continuous Improvement: Foster a culture of continuous improvement where employees are empowered to identify inefficiencies and implement solutions proactively.

- Value Stream Mapping: Map out the entire warehouse workflow to identify bottlenecks, redundancies, and areas for optimization.

2. Optimize Layout and Organization

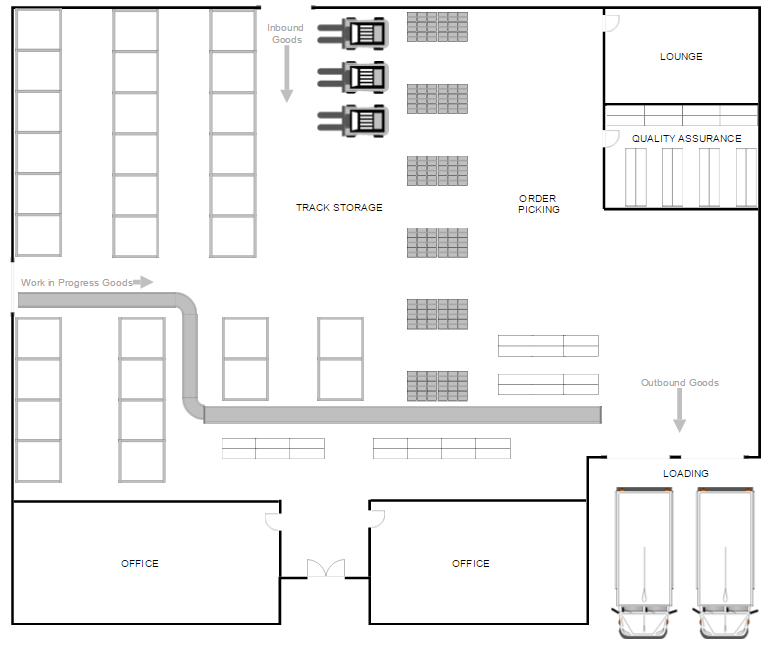

Maximize space utilization and workflow efficiency through strategic warehouse layout and organization:

- Zone Picking: Divide the warehouse into zones based on product categories or order types to minimize travel time and optimize picking routes.

- Vertical Storage: Utilize vertical space with mezzanine floors, tall shelving units, or automated storage systems to increase storage capacity without expanding the footprint.

- Clear Signage and Labeling: Clearly label aisles, shelves, and storage locations to facilitate easy navigation and accurate picking.

3. Invest in Technology Solutions

Leverage technology to automate processes, improve accuracy, and enhance visibility:

- Warehouse Management System (WMS): Implement a WMS to optimize inventory control, order fulfillment, and warehouse operations management.

- Barcode Scanning and RFID: Utilize barcode scanning and RFID technology for real-time inventory tracking, picking accuracy, and error reduction.

- Automation and Robotics: Explore automation solutions such as conveyor systems, automated guided vehicles (AGVs), and robotic picking systems to increase throughput and minimize manual labor.

4. Streamline Order Fulfillment

Enhance order fulfillment processes to meet customer demands efficiently:

- Batch Order Processing: Consolidate similar orders into batches to reduce order picking and processing time.

- Wave Picking: Implement wave picking strategies to group orders by common characteristics or delivery routes, optimizing picking efficiency.

- Cross-Docking: Introduce cross-docking practices to expedite the transfer of goods from receiving to shipping without intermediate storage.

5. Prioritize Employee Training and Engagement

Invest in comprehensive training programs and empower employees to contribute to warehouse improvement initiatives:

- Training and Development: Provide regular training sessions to enhance employee skills in areas such as forklift operation, inventory management, and safety protocols.

- Employee Recognition Programs: Recognize and reward employees who demonstrate exceptional performance, innovation, and commitment to improving warehouse efficiency.

- Feedback Mechanisms: Encourage open communication channels for employees to provide feedback, suggestions, and ideas for warehouse improvement.

6. Enhance Safety and Ergonomics

Promote a safe and ergonomic work environment to reduce injuries and improve productivity:

- Safety Protocols: Implement strict safety protocols, including proper equipment usage, hazard identification, and emergency procedures.

- Ergonomic Equipment: Invest in ergonomic warehouse equipment such as adjustable workstations, lifting aids, and anti-fatigue mats to reduce strain and injuries among warehouse staff.

- Regular Inspections: Conduct regular safety inspections and audits to identify potential hazards and address them promptly.

Conclusion

By applying these methods and concepts, interior designers can unleash the complete potential of their operations, boosting efficiency, productivity, and client satisfaction. In an Ocotillo warehouse, through optimizing layout and organization, embracing tech solutions, or prioritizing employee engagement, continuous improvement stands as the cornerstone for success in the ever-changing realm of warehouse management. By remaining agile, adaptable, and proactive, Ocotillo Services receiving warehouse serving Indio can effectively tackle the challenges of today’s marketplace and establish themselves as pioneers in warehouse efficiency and productivity, enhancing the entire interior design community.